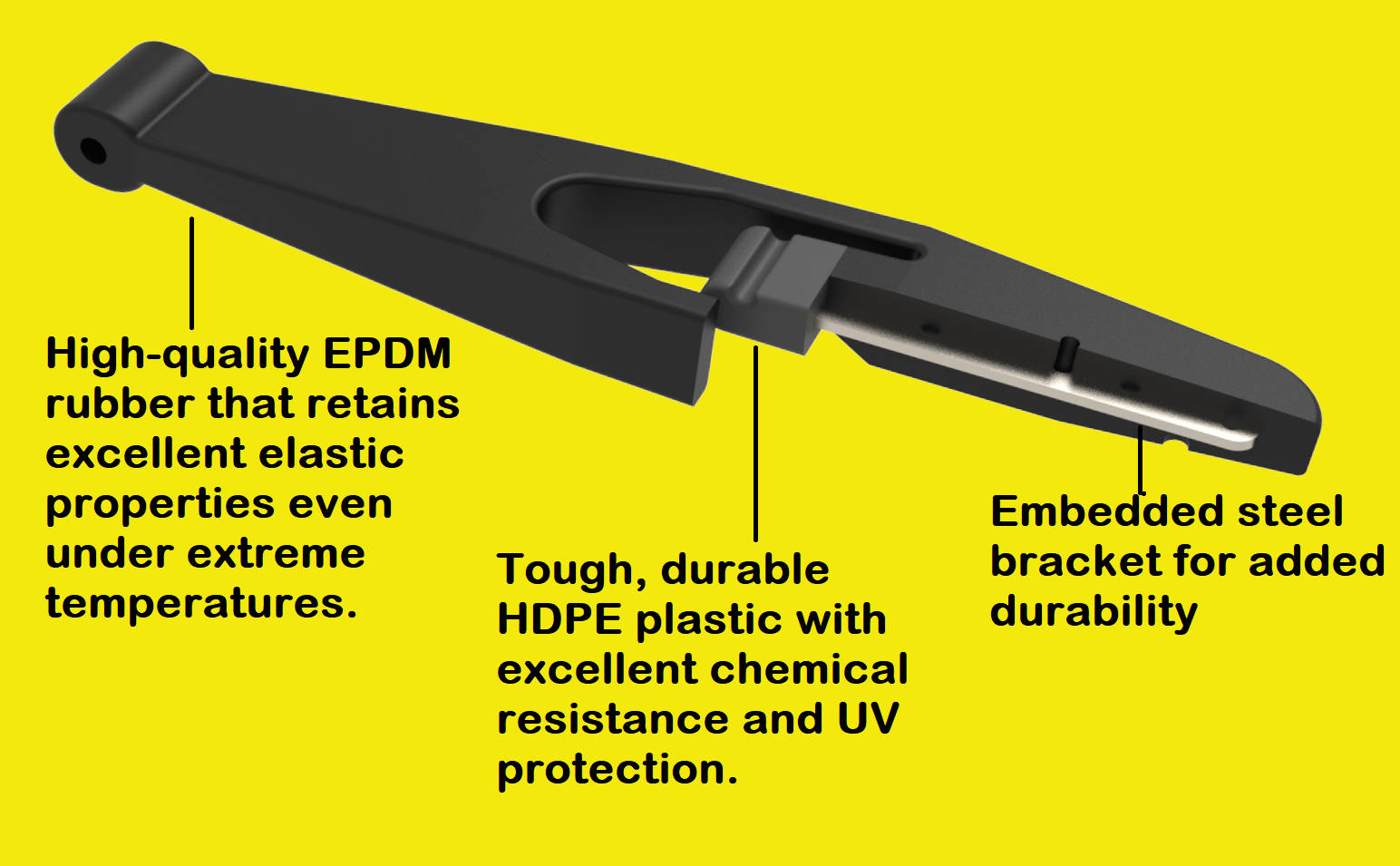

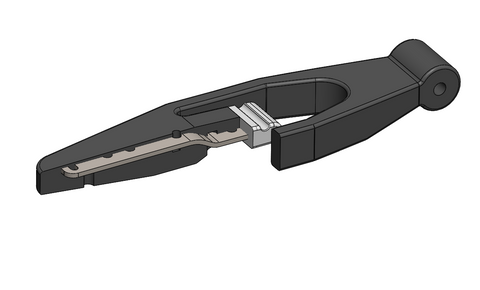

Commercial trucks like Freightliner, Peterbilt, Volvo, Midwest WA, and Western Star are built to endure the rigors of the road, carrying heavy loads over long distances under various environmental conditions. Among the myriad of components that ensure the durability and reliability of these vehicles, the hood latch plays a pivotal role. Yet, it is often overlooked until issues arise. Our latest innovation in hood latch design addresses common failings head-on, offering a solution that outmatches any other on the market: the EDPM rubber hood latch, enhanced with embedded steel.

Why EPDM Rubber Stands Out

Ethylene Propylene Diene Monomer (EPDM) rubber is a synthetic rubber known for its outstanding heat, ozone, and weather resistance. When it comes to the engine compartment of a truck, the hood latch is constantly exposed to high temperatures and environmental stress. Here's why EPDM rubber is your hood latch's best defense:

Heat Resistance

EPDM maintains its structural integrity and elasticity under temperatures that would cause other types of rubber to deteriorate. This makes it an ideal choice for areas close to the engine, where heat can be intense.

Elasticity Maintenance

The constant opening and closing of the truck's hood demand a material that can stretch and return to its original shape without fail. EPDM rubber's superior elasticity ensures that our hood latches will perform reliably over time, avoiding the common issue of becoming loose or unresponsive.

Ozone and Weather Resistance

Commercial trucks travel through various climates, from the scorching heat of deserts to the freezing cold of mountain passes. EPDM rubber's resistance to ozone and varying weather conditions means that our hood latches are built to last, no matter where your journey takes you.

The Strength of Embedded Steel

To further enhance the durability and performance of our hood latches, we've incorporated embedded steel within the EPDM rubber. This combination provides:

- Increased Strength: The steel reinforcement ensures that the latch can withstand the physical stresses of frequent use without compromising its integrity.

- Durability: The added strength from the steel extends the life of the hood latch, making it a cost-effective solution for fleet maintenance.

|

|

|

|

|

|

In conclusion, our EPDM rubber hood latch with embedded steel represents a significant leap forward in commercial truck maintenance and performance. Designed to withstand the harshest conditions without losing elasticity or strength, it's the ultimate solution for ensuring your hood latch meets the same high standards as the rest of your vehicle. Upgrade your fleet today and experience the difference.

Our Available OE Replacement Part Numbers

Find high-quality aftermarket hood latches for commercial trucks, including Freightliner, Peterbilt, Volvo, Western Star, Oshkosh, and Midwest WA. Our durable, easy-to-install latches replace OE part numbers: 17-12348-000, 17-12438-000, 671010002, 671010005, 671010006, 671010007, 671010008, 8174018, 23-13857, L56-0001, 63011005A, 63011005, 2313857, L560001, Peterbilt 1304339, Peterbilt 23-13857, Peterbilt L56-0001, Freightliner 680-880-016, Freightliner 680-880-01-60, Western Star 1712434000, Freightliner 17-12438-000, WA188015, Oshkosh 2071290, A1712438000, HLK1024, FLD 120 Classic, Volvo HLK 1028K, V1118205, 3QM39B, DM Models FHL-4546, FLD12064ST, 17-12435-001, 1712435001, HLK1012K, 17-12435-000, HLK1011K, FTL A17-15553-000, HLK1019, 3155203CD, and A17-15553-001. Ensure a secure, lasting fit for your truck.